The Fascinating Ways in Which Breakfast Cereals are Made

Americans eat nearly three billion boxes of cereal every year. And yet few of us know how Rice Krispies, Corn Pops, or any other cereal is made. Here’s a look at the science behind some of our favorite breakfast foods.

Americans eat nearly three billion boxes of cereal every year. And yet few of us know how Rice Krispies, Corn Pops, or any other cereal is made. Here’s a look at the science behind some of our favorite breakfast foods.

NATURAL-BORN POPPER

Popcorn for breakfast? It’s not the first thing most people think of eating in the morning, and it’s not marketed as a breakfast food. But popcorn does have many of the qualities that cereal manufacturers look for in a breakfast food: It’s light and airy, it’s crispy, and it crunches when you eat it. If you put some popcorn in a bowl and poured milk over it, it would probably stay crunchy at least as long as your favorite breakfast cereal does.

But what about foods that don’t pop naturally the way that popcorn does? Quite a bit of the technology used in the manufacture of breakfast cereals is employed specifically to make those foods “poppable”—to produce desirable, popcorn-like qualities in foods that don’t normally have them- foods like whole-grain rice and wheat, for example. Or grains that have been milled into flour, then mixed with other ingredients to make dough that is then baked into individual pieces of cereal.

POPCORN 101

To understand how whole grains and dough end up as Puffed Wheat, Cheerios, and Kix, it helps to understand what makes popcorn pop in the first place.

- A kernel of popcorn consists of a hard shell that surrounds a dense, starchy center, and there’s a lot of moisture in the starch. When you place a bag of unpopped popcorn in a microwave oven, the microwave “cooks” the popcorn by heating the moisture in the starch. The starch softens and develops a consistency similar to gelatin as it cooks.

- When the moisture is heated to the boiling point, it converts into steam and begins to expand. Or at least it wants to: What makes popcorn different from most other grains is that its hard outer shell does not allow the steam to escape. Instead, the kernel of corn becomes like a tiny pressure cooker: The steam pressure builds up until the outer shell can no longer contain it, and it ruptures.

- If you’ve ever opened a bottle of champagne or a shaken bottle of soda, or squirted a dollop of shaving cream into your hand, it’s easy to understand what happens next: When the shell cracks, the pressure drops and the moisture in the starch instantly converts from a liquid state to a gaseous state, creating air bubbles in the cooked, gelatinous starch that cause it to froth up into a foamy mass, expanding it to 30 or 40 times its original size. The steam escapes, leaving behind the dried, crunchy, styrofoamy starch that we know as popcorn.

POP! GOES THE CEREAL

Wheat and rice don’t have external shells that trap steam the way that corn does, so if you want to obtain popcornlike results with these grains, you have to provide the pressure cooker. When cereal companies want to make puffed wheat, puffed rice, or puffed dough, they do just that, using a process known as “gun puffing” developed by Quaker Oats researchers at the turn of the 20th century. Why is it called gun puffing? Because the process was perfected using an actual Army cannon—one that saw action in the Spanish American War—that was converted into a pressure cooker. (Corn kernels can also be gun puffed. That’s how Kellogg’s Corn Pops are made.)

Corn Pops, Puffed Wheat, and Puffed Rice

- Whole grains are steam cooked in a pressure cooker (or cannon) until the pressure builds to about 200 pounds per square inch (psi), or about 13.6 times the normal atmospheric pressure (at sea level).

- When the grains have been properly cooked, the pressure inside the pressure cooker is released all at once, just like when popcorn pops. There’s even a loud POP! when the pressure is released.

- The sudden drop in pressure causes the moisture in the grains to flash into steam, puffing up the grains just like popcorn.

- The puffed grains are baked dry, and in the case of puffed-wheat cereals like Kellogg’s Honey Smacks and Post Golden Crisp, lots of sweeteners are added to make them more appealing to kids.

“Extruded” Gun-Puffed Cereals Made From Dough

How do they make Kix, Trix, Cheerios, Alpha Bits, Cocoa Puffs, and other “extruded gun-puffed” cereals?

- Various combinations of corn, oat, wheat, and rice flours are mixed with sugar, water, coloring, flavoring, and other ingredients to make a sweet dough, which is then fed into a machine called a forming extruder.

- The extruder forms the dough into the desired shape just like you might have done if you played with Play-Doh when you were a kid: To create a star shape, you squeeze, or extrude, the dough through a star-shaped hole. If you want a round shape, you squeeze the dough through a round hole. If you’re making Cheerios, you punch a hole in the middle to get a donut shape, and if you’re making Alpha Bits, you use letter-shaped holes.

- As the extruded dough emerges from the hole in the proper shape, rotating blades cut it into individual cereal pieces.

- The freshly extruded dough pieces have too high a moisture content to be suitable for gun puffing, so they are dried until their moisture content drops from as high as 24% down to a more desirable 9% to 12%. (Unpopped popcorn kernels, by comparison, have a moisture content of 13.5% to 14%.)

- The dried pieces are fed into a gun puffer. The puffed cereal is then toasted dry.

RICE KRISPIES

If you’ve ever watched cookies bake in the oven, you know that the dough puffs as it cooks. Rice Krispies are made the same way, in a process that’s called “oven-puffing.”

- First, rice is pressure cooked at a low 15–18 psi (vs. the 200 psi used in the gun-puffing process) with water, sugar, salt, flavoring, and other ingredients.

- The cooked rice is then dried to reduce the moisture content from 28% to 17%; then it is “bumped,” or fed through rollers to flatten the grains slightly and create small cracks in the rice, which will aid puffing.

- The cooked, bumped rice is dried a second time to bring the moisture content from 17% down to around 10%, which is ideal for oven-puffing. The grains are then fed into a rotating oven and baked at 550°–650°F for about 90 seconds to give them their distinctive puffy appearance and crunchy texture.

- So what causes the famous Snap! Crackle! Pop! sound? The walls of the puffed Rice Krispies kernels are so thin and brittle that many of them collapse when they come into contact with milk.

CORN FLAKES AND BRAN FLAKES

Looking into a bowl of Corn Flakes or Raisin Bran, it’s easy to imagine that all those flakes started out as one single sheet of cereal that was crumbled into a thousand individual flakes. But that’s not how they’re made.

- It turns out that it’s much easier to make each flake separately. In the case of corn flakes, kernels of corn are processed to remove the hard outer shell and the germ, the part of the kernel that would have grown into a corn stalk if the kernel had been planted as a seed. What’s left after the shell and the germ are removed? Chunks of starch, each of which will become an individual corn flake.

- The chunks are cooked in a solution of water, sugar, salt, flavoring, and other ingredients until the hard, white starch has become soft, translucent, and a light golden brown in color.

- The cooked corn is fed into “de-lumping” equipment to break up any clumps; then it’s dried in a hot-air dryer and fed through giant rollers to flatten the chunks of corn into flakes.

- The flakes are toasted until they reach the proper golden color and have a moisture content of 1.5 to 3 percent.

- Bran flakes are made pretty much the same way, except that whole grains, not chunks, are used to make the flakes. Flaked cereals can also be made from rice or from dough.

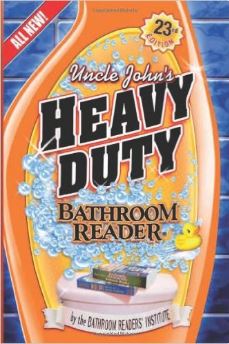

This article is reprinted with permission from Uncle John’s Heavy Duty Bathroom Reader. The big brains at the Bathroom Readers’ Institute have come up with 544 all-new pages full of incredible facts, hilarious articles, and a whole bunch of other ways to, er, pass the time. With topics ranging from history and science to pop culture, wordplay, and modern mythology, Heavy Duty is sure to amaze and entertain the loyal legions of throne sitters.

This article is reprinted with permission from Uncle John’s Heavy Duty Bathroom Reader. The big brains at the Bathroom Readers’ Institute have come up with 544 all-new pages full of incredible facts, hilarious articles, and a whole bunch of other ways to, er, pass the time. With topics ranging from history and science to pop culture, wordplay, and modern mythology, Heavy Duty is sure to amaze and entertain the loyal legions of throne sitters.

Since 1987, the Bathroom Readers’ Institute has led the movement to stand up for those who sit down and read in the bathroom (and everywhere else for that matter). With more than 15 million books in print, the Uncle John’s Bathroom Reader series is the longest-running, most popular series of its kind in the world.

If you like Today I Found Out, I guarantee you’ll love the Bathroom Reader Institute’s books, so check them out!

| Share the Knowledge! |

|

How is a cereal like captain crunch made, I assume it is extruded but it seems to be air entrained.